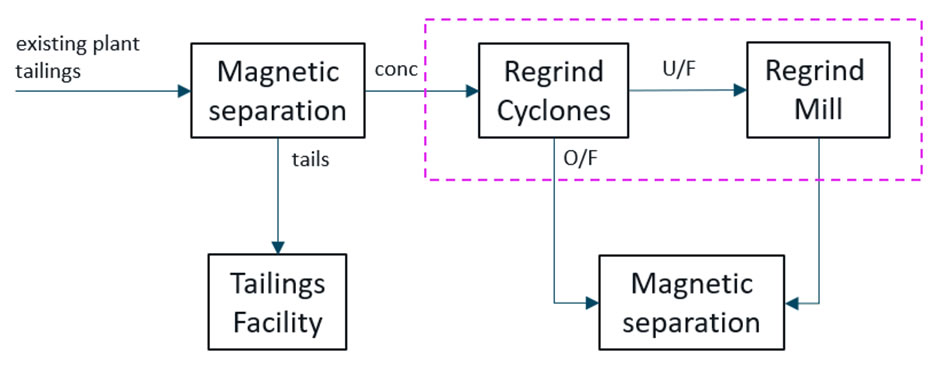

The design of a magnetite recovery circuit, featuring multiple stages of magnetic separation and a regrind circuit.

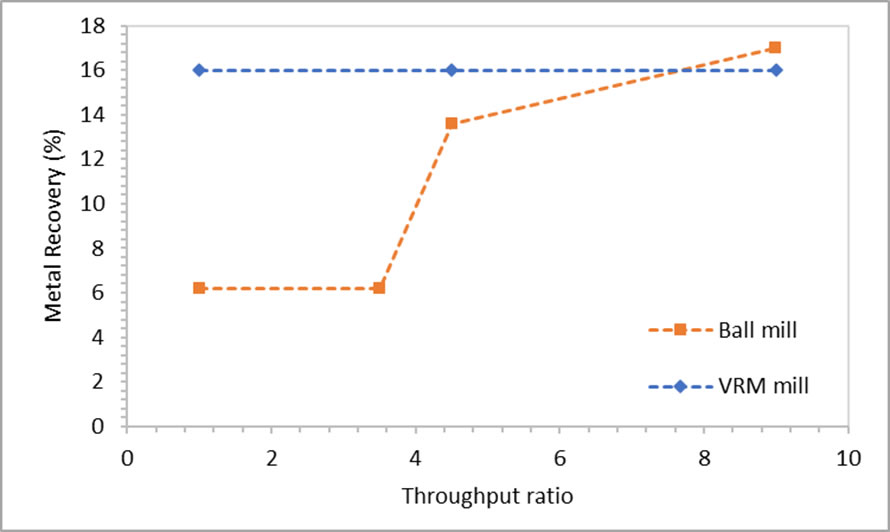

This case consists of the design of a magnetite recovery circuit, featuring multiple stages of magnetic separation and a regrind circuit. The regrind circuit throughput has a range over 9 times during a 10-year operating period due to the varying sulphur and magnetite grades across the mine schedule.

Magnetite Regrind Circuit Technology Comparison

| Ball Mill | VRM |

|---|---|

| The ball mill power draw can only be reduced by varying mill speed and ball charge (lowering ball charge can be challenging as it takes significant time), and only allows the power draw to be reduced 35%. | The power draw of the vertical stirred mills can be varied from 100% to 30% of the installed power in the short-term via the variable speed drive |

| At higher magnetite feed grades, the mill would operate at the maximum throughput and produce a product grind size coarser than target, whereas at lower magnetite feed grades the opposite would occur and finer grind size would be produced. | The media can be changed over the medium term by addition at the top, or removal from valve in the base. Varying the filling can allow the VRM mill to draw below 10% of the installed power. |

| Multiple ball mill units would be required to achieve the target grind size while covering the range of throughput required for the project. | In the long term, the required feed valve assembly is at two different diameters for high feed rates and low feed rates to maintain slurry velocity. |

| As the ball mill operates in closed circuit, it is likely that it would produce more fines by both the preferential deportment of high-density minerals to the cyclone underflow and the non-discriminatory breakage mechanism within the mill. | The combination of open circuit operation and the internal classification within the VRM mill reduces the potential production of fines, thereby increasing downstream recovery. |